For more flexibility

Modular construction uses a technology that enables the production of 3D modules under controlled factory conditions, which are then delivered to the construction site and assembled into a finished building on site.

Simply efficient

With modular construction, all work processes are carried out under controlled factory conditions. This construction technology differs not only in its weather resistance, but also in its predictability, its solution to HR challenges, its guarantee of work safety and its reduction of labor, material waste and dirt. In addition, it requires fewer deliveries to the construction site, ensures a high final quality of the construction project and is faster than conventional construction methods.

MIN

Logistics costs

MAX

Overview of duration and costs

Naturally. Wood.

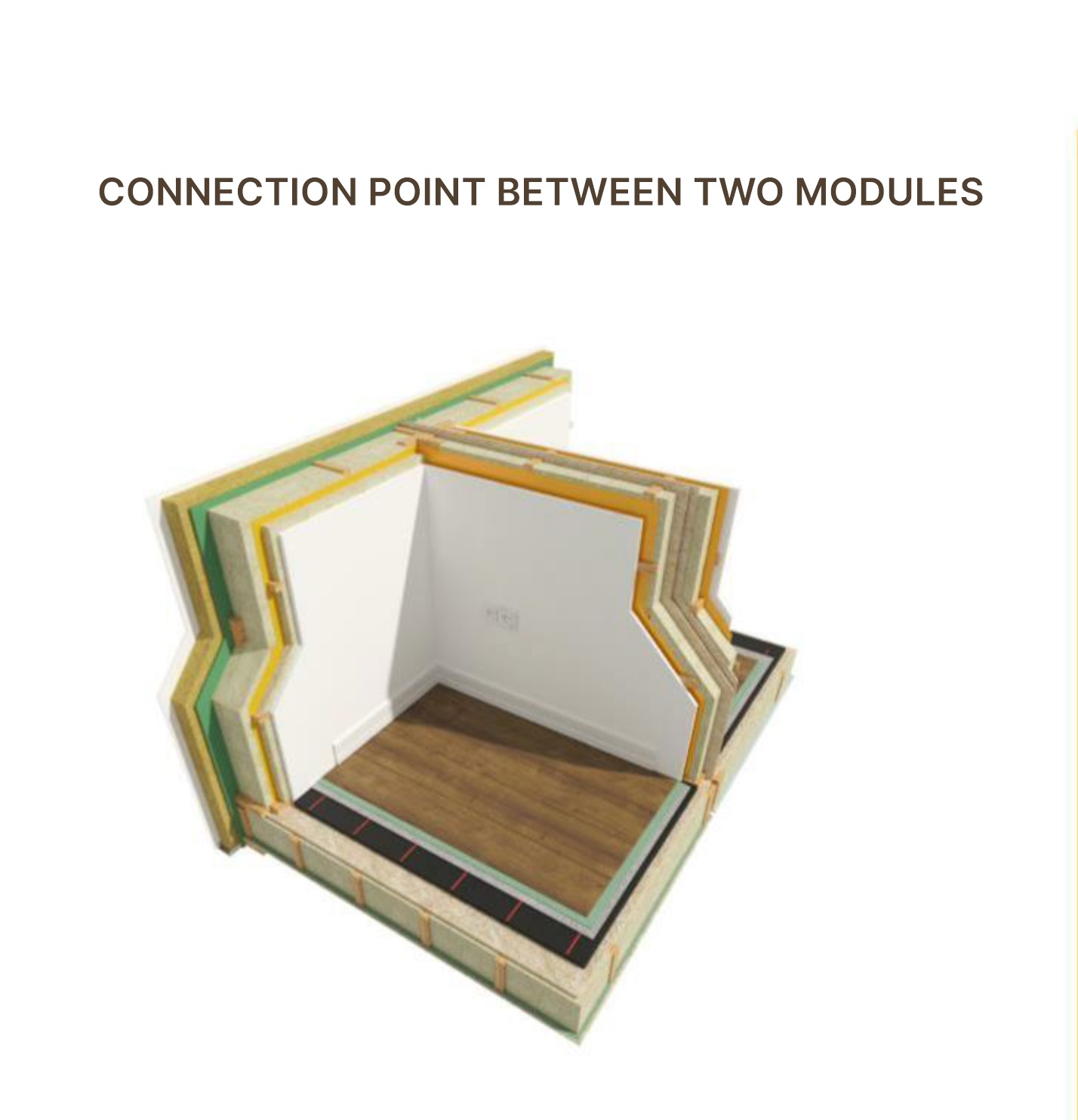

Room cells are large building elements in the form of fixed self-supporting elements. They are designed in such a way that they can be joined together to form complete buildings without additional load-bearing structures.

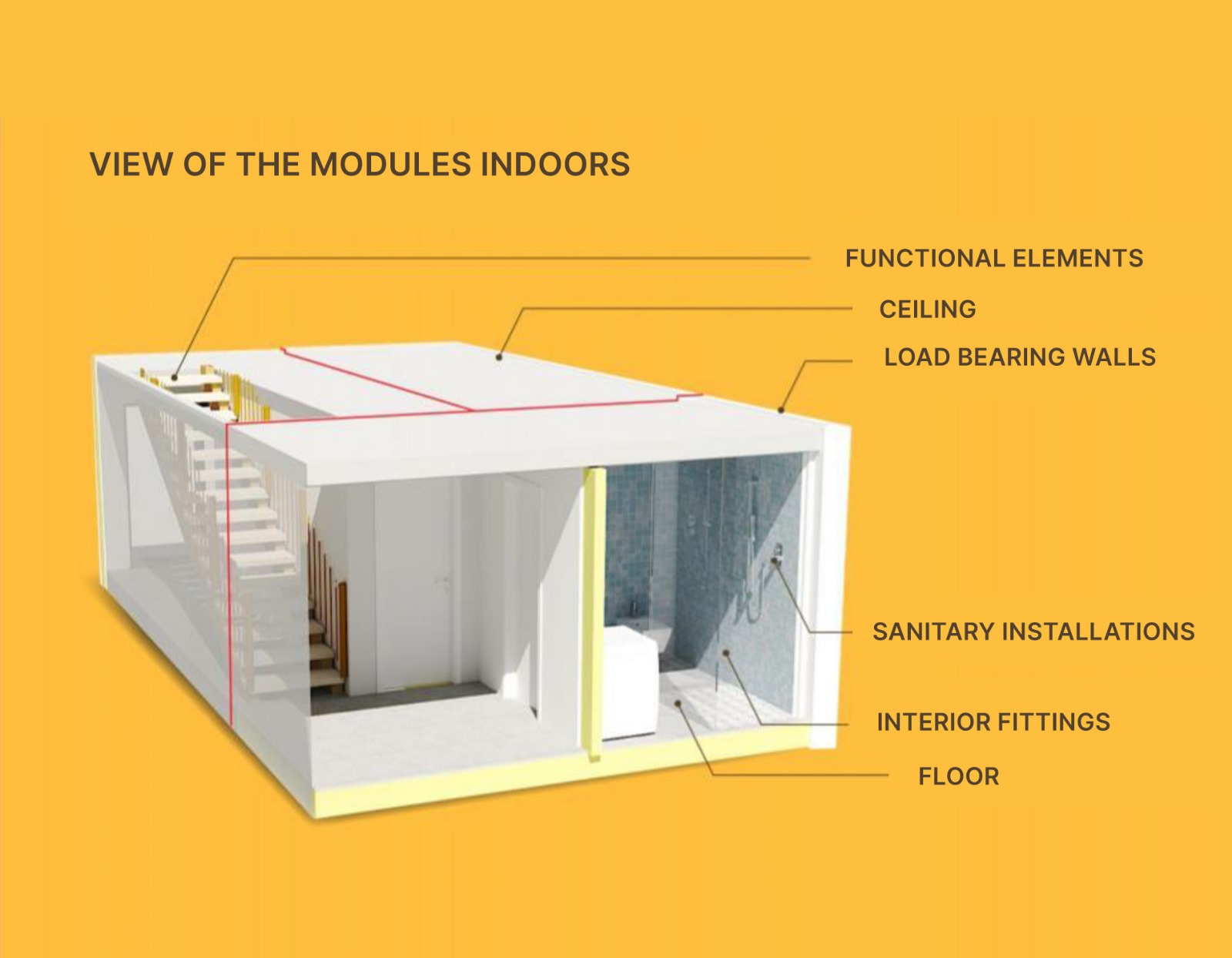

We manufacture modules from a timber base and pre-fits them with electrics, plumbing, heating, ventilation, doors, windows and interior fittings. All of these processes are carried out before dispatch from the factory to minimize defects and ensure a high level of quality control. Modules are then transported to the construction site and carefully assembled on prepared foundations.

How it works

The degree of completion of room cells can already be 95% before assembly, which has been made possible by advances in the field of data modeling (BIM). The finished modules are transported to the construction site and assembled using a crane. As a result, the building is assembled quickly, with virtually no noise and no dirty work.

By producing 3D modules in advanced factories, modular construction opens up an innovative perspective for building projects in the construction industry. These modules, often referred to as room cells, are produced under strict quality standards and then transported to the construction site. The innovative method enables precise prefabrication, resulting in faster and more cost-efficient assembly on site. The adaptability of this construction method opens up new possibilities for a wide range of building projects.

Modular construction not only offers excellent weather resistance, but also predictability in the construction process. By relocating work processes to controlled factory conditions, personnel challenges are minimized. This not only leads to greater workplace safety, but also a reduction in labor, material waste and dirt. This innovative construction method is not only ecologically sustainable, but also ensures high final quality and accelerated construction times.

Room cells, which are considered key components of modular construction, are large, self-supporting building elements. These are designed so that they can be assembled into complete buildings without additional supporting structures. The flexibility in design and adaptability to different construction projects makes these building elements particularly attractive.

The assembly process on the construction site is characterized by its efficiency. The high level of sophistication of room cells before assembly, achieved thanks to advances in data modeling (BIM), enables precise and quick assembly. The use of cranes not only ensures smooth assembly, but also virtually noiseless and dirt-free assembly.

Prefabricating the modules offers numerous benefits, including accelerated assembly, minimized defects and increased final quality. Electrical, plumbing, heating and other elements are integrated at the factory, making the construction process more efficient and cost-effective.

Modular construction minimizes environmental impact by significantly reducing labor, material waste and dirt on the construction site. This environmentally friendly approach helps to realize sustainable construction projects while conserving resources.

Data modeling (BIM) plays a central role in modular construction by enabling precise planning and execution. By optimizing the level of skill of the room cells before assembly up to 95 %, BIM contributes to efficient construction.

Modular construction is ideal for projects that require quick construction time, high quality control and flexibility. From residential buildings to office complexes to educational institutions – modular construction adapts to different requirements.

The ECM Building Group is your choice as a provider of modular construction due to our extensive experience and numerous successfully completed projects. We have proven in various construction projects, from residential buildings to commercial structures, that we not only produce high-quality wooden modules, but also have the skills to meet complex requirements precisely and efficiently.

The ECM Building Group stands for reliability and commitment. If you are looking for a partner with experience in sustainable construction, we are the right choice for your next construction project.

We would be happy to provide you with further information and individual advice on modular construction and MODULWOOD products. Contact us to receive detailed information and learn more about the innovative design. We are happy to share our expertise and support you with your individual construction projects.